In its simplest form, a technician logging the temperature of an oven on a piece of paper is performing data acquisition. In a more complex example, data acquisition can involve the monitoring and collecting of data from a large-scale industrial process with multiple interconnected sensors and variables.

Today, DAQ systems play a vital role in a variety of applications, including in manufacturing, industrial processing, industrial automation, IIoT, quality control, and scientific research. By utilizing sensors and measurement devices, a DAQ system serves as a focal point in a system, tying together a wide variety of products – such as sensors that indicate temperature, flow, level, and pressure.

Features of a DAQ System

A basic DAQ system consists of four parts:Sensors

Sensors and/or transducers interact with the subject measured, either directly or indirectly (contact or non-contact). The convert the physical values to electrical signals. The type of sensors used in a DAQ system varies based on the nature of its application. For example, the measurement of temperature requires a temperature sensor, while a photovoltaic sensor is useful for measuring light. Their common function is to convert analogic signals – like light, temperature, speed, etc. – into digital signals for the computer. DAQ systems employ high-quality sensors that give accurate readings with minimal or no noise.Transmission/Signal Conditioning

The electrical signals impending from the sensors cannot be utilized directly, as modification is needed. This modification is necessary because the signals often contain noise or might be weak to a point where the DAQ system cannot measure it.As such, a signal conditioner is used to optimize the signals. The signal conditioner operates by using filter circuits to separate the noise from the real signal and uses an amplification circuit to strengthen weak signals. These are two of the common functions that they undertake.

With a suitable signal conditioning circuit, there are even more processes – like calibration, linearization, and excitation – that become achievable. The selection of the signal conditioning circuit largely depends on the characteristics of the sensor.

DAQ Hardware

DAQ hardware is the hardware entity connected between the computer and the sensors. DAQ hardware is either connected to the computer using the USB ports or through the PCI-Express slots on the motherboard.The DAQ hardware takes in the analog signals from the sensors and converts them to digital signals readable by the computers. But, this just one of the functions of DAQ hardware.

Some of the common features in a DAQ system are:

- ADC: Converts analog signals into digital signals.

- Digital to Analog Converter: Support for inputting and outputting binary signals.

- RS232, RS485: Interface busses used to communicate with other devices.

- Single-Ended Input: Support for taking input from single-ended wires.

Computer

The end piece of the DAQ chain is a computer that gathers all the data coming through the DAQ hardware for further analysis. However, connecting the DAQ hardware to a computer is not enough to make sense of the data. That requires DAQ software that uses the data from the DAQ hardware to create readable and meaningful results. As such, the DAQ software acts as the layer between the user and the DAQ hardware. Computers are critical to be able to perform higher-order computations with the data collected from the DAQ.What Do DAQ Systems Measure?

DAQ systems are utilized to measure a wide range of physical and electrical parameters. Some of the common measurements performed by a DAQ system include:Temperature Measurement

DAQ systems can measure temperature using thermocouples, resistance temperature detectors (RTDs), or thermistors.

Pressure Measurement

DAQ systems can measure pressure using pressure transducers or pressure sensors.

Voltage Measurement

DAQ systems are capable of measuring voltage levels from various voltage signal sources – such as sensors, power supplies, or electrical currents.

Current Measurement

DAQ systems can measure electrical current flowing through a current using current sensors or transducers.

Strain Measurement

DAQ systems can measure strain using strain gauges, which are commonly used in structural analysis or material testing.

Flow Measurement

DAQ systems can measure fluid flow rates using flow meters or flow sensors.

Force Measurement

DAQ systems can measure force or load using load cells or force sensors, which find applications in materials testing and force analysis.

Acceleration Measurement

DAQ systems measure acceleration using accelerometers, commonly used in vibration analysis and motion detection.

Humidity Measurement

DAQ systems can measure humidity levels using humidity sensors, which are important in environmental monitoring and HVAC systems.

Light Intensity Measurement

DAQ systems can measure light intensity using photodetectors or light sensors, allowing applications like light intensity monitoring and optical analysis.

Choosing the Right Data Acquisition System

There are various types of DAQ systems available, each designed for specific applications and requirements. Some examples include:Wireless Data Acquisition Systems

Wireless DAQ systems can eliminate the need for field wiring process sensors – which is both costly and time consuming. Theses systems consist of one or more wireless transmitters sending data back to a wireless receiver connected to a remote computer. Wireless transmitters are available for ambient temperature and relative humidity, thermocouples, RTDs, pulse output sensors, 4 to 20 mA transmitters, and voltage output transducers. Receivers can be connected to the USB or Ethernet port on the PC.Serial Communications Data Acquisition Systems

Serial communications DAQ systems are a good choice when the measurement needs to be made at a location which is distant from the computer. There are several different communication standards – RS232 being the most common but limited in that it only supports transmission distances of up to 50 feet. RS485 is superior to RS232 and supports transmission distances of up to 5,000 feet.USB Data Acquisition Systems

The Universal Serial Bus (USB) is a standard for connecting PCs to peripheral devices – such as printers, monitors, modems, and data acquisition devices. USB offers several advantages over conventional serial and parallel connections, including higher bandwidth (up to 12 Mbits/s) and the ability to provide power to the peripheral device. USB is ideal for data acquisition applications. Since USB connectors supply power, only one cable is required to link the data acquisition device to the PC, which most likely has at least one USB port.Data Acquisition Plug-In Boards

Computer data acquisition boards plug directly into the computer bus. Advantages of using boards are speed (because they are connected directly into the bus) and cost (because the overhead of packaging and power is provided by the computer). Boards offered are primarily for IBM PC and compatible computers. Features provided by the cards can vary due to number and type of inputs (voltage, thermocouple, on/off), outputs, speed, and other functions provided. Each board installed in the computer is addressed at a unique Input/Output map location. The I/O map in the computer provides the address locations the processor uses to gain access to the specific device as required by its program.When choosing the right DAQ system, there are a variety of factors to consider, including:

- Measurement Requirements

- Sensor and Transducer Compatibility

- Software and Interface Compatibility

- Expandability and Scalability

- Adequate Signal Conditioning

- Cost

Benefits of Using DAQ Systems and DAQ Devices

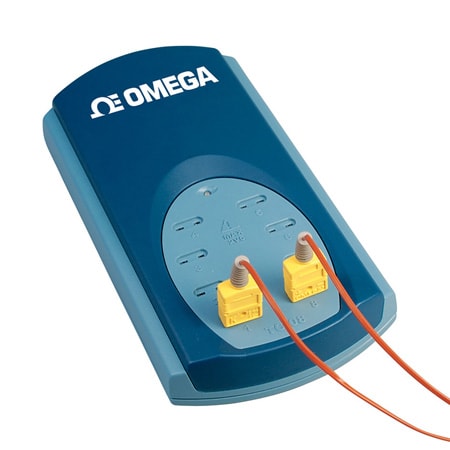

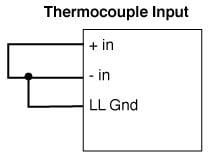

DAQ systems and devices offer many benefits in data acquisition and measurement processes. Some of these key benefits include: Thermocouple Input

Industry Leading Devices

Thermocouple Input

Industry Leading DevicesThe first and foremost benefit of DAQ systems and devices is that they are adopted worldwide. The ability of DAQ devices to connect with different sensors and work in tandem with modern computers makes them a prime choice for engineers, researchers, and scientists who are looking to get reliable data.

Accurate and Reliable Measurement

DAQ systems provide high measurement accuracy and precision, ensuing reliable data acquisition. They minimize signal noise, offer calibration capabilities, and enable precise measurement of various parameters.

Wide Range of Signal Compatibility

DAQ systems can interface with diverse types of sensors and transducers – allowing measurements of analog, digital, and specialized signals. They support multiple input types, such as voltage, temperature, pressure, strain, and more.

Real-Time Monitoring and Analysis

DAQ systems facilitate data logging, capturing, and storing measurement data over time. This feature enables long-term analysis, trend identification, and post-processing of acquired data. Automation and Efficiency: DAQ systems automate the data acquisition process, reducing the need for manual data recording and minimizing human error. This automation improves overall efficiency, enabling continuous and unattended data collection. Highly Versatile DAQ systems are used in applications across various fields, including scientific research, industrial processing, quality control, environmental monitoring, manufacturing, and healthcare. They can adapt to different industries and measurement needs.

Flexibility and Scalability

DAQ systems offer flexibility in terms of configuration and scalability. They can be easily expanded by adding more channels or modules to accommodate changing measurement requirements.

Enhanced Data Analysis and Visualization

DAQ systems often come with powerful software tools that allow users to perform advanced data analysis, visualization, and interpretation. These tools assist in extracting meaningful insights from acquired data.

Remote Monitoring and Control

Some DAQ systems support remote monitoring and control capabilities, enabling users to access and manage data from distant locations. This feature is beneficial for distributed systems or inaccessible environments.

Improved Decision-Making

By providing accurate and reliable data, DAQ systems support informed decision-making processes. The insights gained from data analysis and visualization help identify patterns, anomalies, and trends – leading to better outcomes.

Cost

DAQ systems are capable of measuring multiple properties of a subject, you are eliminating many standalone devices. This brings down the overall cost of your test setup.

Documentation

One of the defining features of a DAQ system is documentation capability. You can perform a varied set of tests one after the other without writing down the results and without the fear of losing the readings as they get automatically recorded on the computer. Documentation eliminates data redundancy.