Application

Heating mantles are commonly used in laboratories to heat liquids as part of the research process. Mantle heaters provide only the container for holding a flask and do not offer any temperature control. In most lab applications there is a need to control temperatures to a tight temperature set point.

In some labs, mantle heater temperature is controlled using a simple variable AC supply, which requires monitoring the temperature manually with a probe and a handheld meter. This method requires careful attention and constant monitoring. A benchtop controller, on the other hand, can provide digital control and resolves the issue of having to monitor the temperature manually. A similar heating arrangement can be used on a hot plate as well.

OMEGA products used in this application

Products

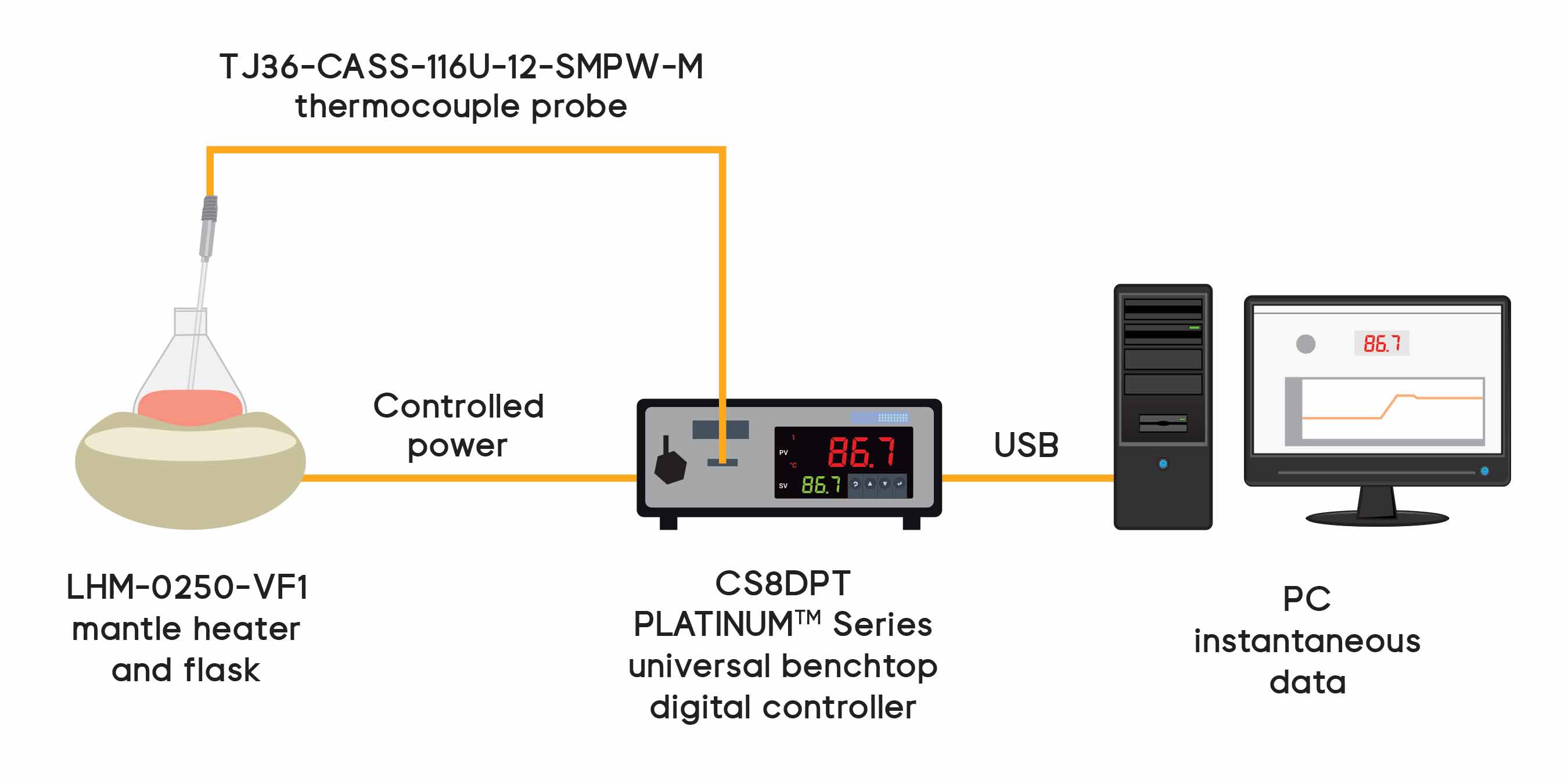

The figure above shows the schematic of the PID-controlled heat source. The application includes three OMEGA products, a plastic casing, high-temperature insulation, an aluminum block, high-heat epoxy, a power cord, wiring connectors, an electronics enclosure box, and high-heat enamel paint:

CLHM0250-HS1: Laboratory heating mantle with proven “self” standing design that can be placed directly on a countertop.

CS8DPT: This portable, high accuracy benchtop controller comes with a large color-changing display and features 4-digit dual LED or 6-digit display. Equipped with universal inputs, the controller handles multiple types of thermocouples and RTDs, thermistors, several process (DC) voltage & current ranges, and strain type of inputs.

5SC-GG-K-30-72: Ready-made insulated glass-braided thermocouple probe with maximum service temperatures of 480°C (900°F).

How it Works

- Plug the mantel heater directly into output 2 of the benchtop control.

- Connect the benchtop via USB to a PC running either Windows 7 or 10.

- Use the configuration program to program the benchtop controller, including temperature set point, range, and sensor type.

- Program the benchmark controller to change color between green, amber, and red to provide a visual indication of temperature range or to create a temperature set point alarm.

- Install the thermocouple probe in thermal well in round bottom flask and plug it into front of controller.

Results

The heating mantle temperature no longer needs to be monitored manually. Visual or auditory alarms can alert lab technicians when temperatures move out of the set point range. Data is also logged automatically and can be viewed on a PC via the configuration program.

Pro Tip

While the benchtop controller can accept a number of input types, a thermocouple is recommended for most applications as it has a wide temperature range, good accuracy, and is low-cost.