Application

When a single conduit line in a complex configuration of pipelines is compromised, it can be challenging to locate the precise point where the leak is occurring. If increased overall water usage is observed when no change in the process was made, it’s probable that one pipe has a crack or fissure.

Testing pipelines throughout the system with a portable ultrasonic flow meter should reveal the leak’s location. The portable flow meter enables operators to compare flow rates and total flow volume at various points in the system. Lower flow volume at a site indicates a leak in its proximity. This method is non-invasive and requires no cutting of pipes.

OMEGA products used in this application

Product

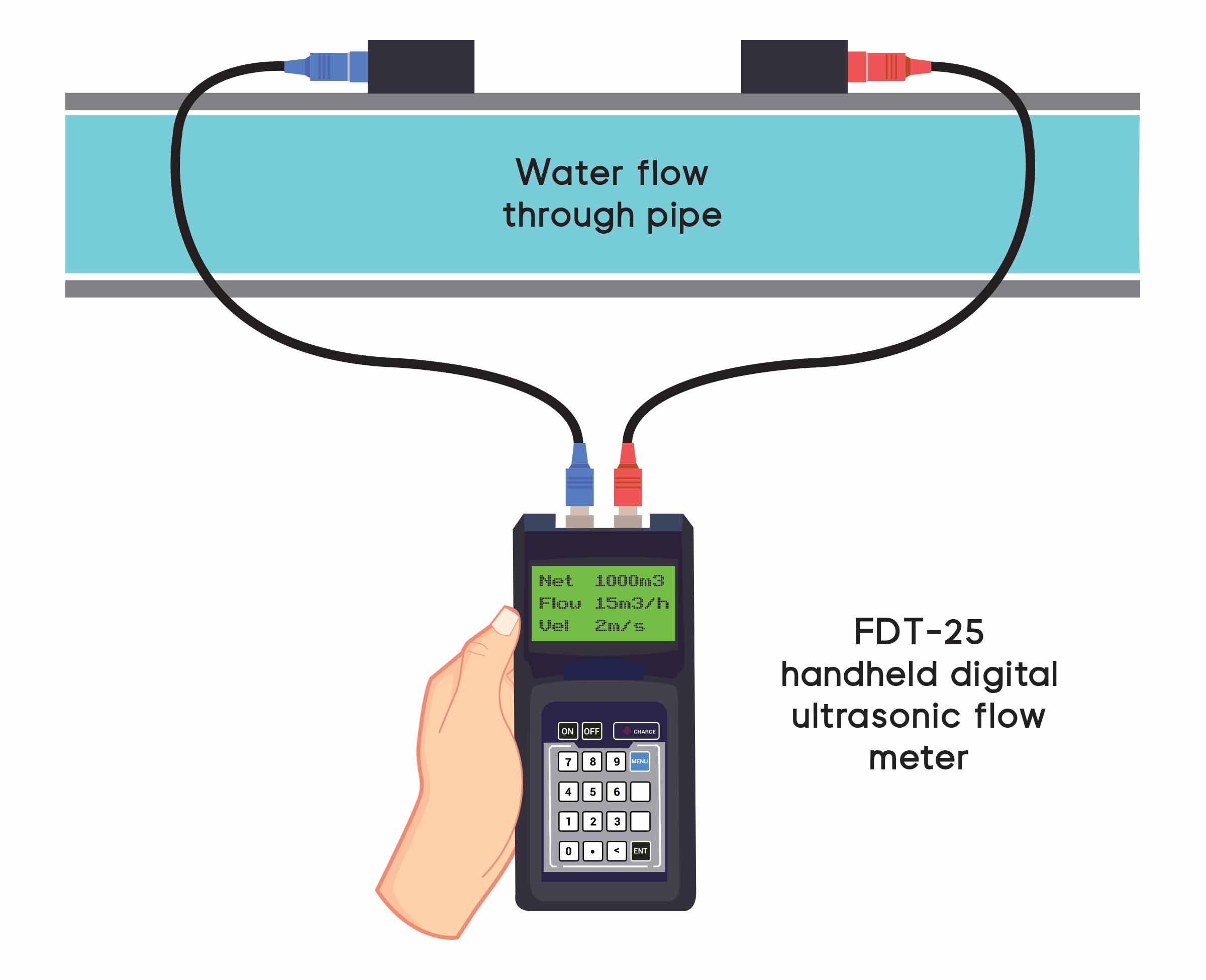

The figure above shows a schematic of the flow meter correctly installed on a straight length of piping. This application requires only a single product:

FDT-25: This handheld portable ultrasound transit line flow meter kit contains all components needed to measure the velocity of a fluid traveling through a full or closed pipe. An ultrasonic pulse is sent through the liquid, and its transit time is measured with two transducers placed on opposite sides of the pipe. Flow velocity is shown on a digital display in units selected by the user. Batteries, transducers, acoustic gel, and charging and transducer cables are included.

How it Works

- Identify a straight run section of pipe to mount the flow meter.

- Ensure that no electrical interference is present and there’s no paint or exterior coating on the pipe.

- Program the meter to specify the pipe size and thickness as well as the type of lining in the pipe.

- Identify the type of fluid the ultrasound transmission will be traveling through if other than water.

- Read mounting method and transducer placement determination provided by the meter.

- Apply gel to the pipe to facilitate a tight seal and then mount the transducer.

- Read and record flow volume results on the meter.

- Move the flow meter from pipe to pipe as needed until leak is identified.

Results

This method enables operators to identify through a non-invasive process the section of pipe with abnormal flow volume. Tracing this pipeline from end to end should reveal the exact location of the leak.

Pro Tip

Examine the pipes carefully and remove any paint or other exterior coating material on the pipe’s surface to avoid interferance. Note that internal corrosion within the pipes can also cause inaccurate measurements. Ensure that you are using an ample amount of acoustic gel, since the meter won’t function accurately without sufficient gel. Additional gel must be introduced each time the flow meter is moved to another pipe.