Proportional integral derivative (PID) control is a well established way of driving a system towards a target position or level. It’s practically ubiquitous as a means of controlling temperature, and finds application in myriad chemical and scientific processes as well as automation.

PID control is however not without problems. It can yield less than ideal results in situations where the target value changes, whether as a step function or as part of a “ramp & soak” profile.

In an effort to improve performance, some instrumentation manufacturers are exploring the value of using “fuzzy logic” for process control. This OMEGA Engineering White Paper explores both the weaknesses of PID systems and the potential benefits of fuzzy logic, with particular reference to issues in temperature control. Individual sections address:

- PID challenges

- Introduction to fuzzy logic for control

- PID plus adaptive fuzzy logic

- Applications

PID Challenges

The mathematics in a PID control equation is complex with multiple variables and constants interacting. In any given application these are selected to follow the target value as closely as possible, within the constraints imposed by the process itself and the instrumentation.

Three issues common to almost every process control application are:

- Time delays or lag

- Step function response

- "Ramp & Soak" function response

PLATINUM Series PID Controller Demonstrator

PLATINUM Series PID Controller Demonstrator

In many situations the output can take a long, and perhaps also variable, time to react to input changes. To give one example, a furnace will cool when “charged” with new metal and could take several minutes to come back up to temperature. This can lead to temperature overshoots which may damage the contents. Alternatively, the heating may be too slow, reducing process efficiency and causing deleterious effects to the product or material.

When the target value changes instantaneously PID forces the system to apply a large correcting factor, which again can lead to overshoot. Alternatively, the system may become saturated, unable to supply sufficient correction, adding to the impact of the “I” term.

These problems also occur in “ramp & soak” situations where temperature is increased gradually then held. Tracking a gradual change in setpoint can challenge PID control systems.

As a result, selecting the optimal values is something of a trial-and-error process known as “tuning.” Over the years many approaches to tuning have been developed, the most satisfactory of which appears to be the “Ziegler Nichols” method. However, this produces high levels of oscillation, which can be problematic in some situations.

Introduction to Fuzzy Logic Control

Conventional computing is based on Boolean logic, meaning everything is represented as either zero or one. In some situations this leads to oversimplification and inadequate results. Fuzzy logic, and by extension, fuzzy control, seeks to deal with complexity by creating heuristics that align more closely with human perception of problems.

Fuzzy Logic is a particular area of concentration in the study of Artificial Intelligence and is based on the value of that information which is neither definitely true nor false. The information which humans use in their everyday lives to base intuitive decisions and apply general rules of thumb can and should be applied to those control situations which demand them. Acquired knowledge can be a powerful weapon to combat the undesired effects of the system response.

Fuzzy logic provides a way of dealing with imprecision and nonlinearity in complex control situations. Inputs are passed to an “inference engine” where human or experienced-based rules are applied to produce an output.

PID Plus Adaptive Fuzzy Logic

Tuning of PID loops depends on heuristics yet often ends up being sub-optimal. Fuzzy logic provides an alternative to approaches such as Ziegler Nichols, and a growing body of research suggests it yields superior results. Thus it would seem an ideal way to control many complex processes is with a PID controller tuned with fuzzy logic.

One commercially available product incorporating such an approach is the OMEGA® Platinum Series of temperature and process controllers. This family of compact microprocessorbased PID controllers, available in three DIN sizes, is designed to be easy to set-up and use. All common thermocouples and RTDs can be connected, with the system automatically enabling only the relevant functions for the input type selected. Voltage and current inputs are also available, allowing use with almost any engineering units. These controllers provide a complete PID solution, supporting complex programs with up to 16 Ramp & Soak sequences. Auto tune is available for PID applications with adaptive fuzzy logic to help attain optimal results.

How do Fuzzy Logic programs work?

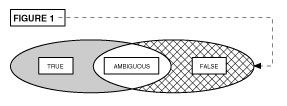

Control software utilizing fuzzy programs use a very flexible set of if-then rules. The solution is then applied to appropriate membership functions. Referring to figure 1, values which lie within the shaded area are called true beyond a shadow of a doubt. Those values which lie within the cross hatched area are called false beyond a shadow of a doubt. If all data falls to one side or the other of the overlap area, then Fuzzy Logic probably would be of little benefit.

In most applications there are some points which lie in the common area. Information which lies within the common area has to be studied, stored, and used to quantify and to classify the data. This allows for smart manipulation of the data structure in order to make inference to a solution. Information which falls in that common area can be ranked, aged, and "best guess" made after evaluation of this "gray" information.

Another benefit of Fuzzy Logic in a control system is to quantify the input signal in a sometimes "noisy" environment. This noise, which tends to corrupt the integrity of the actual signal, is dealt with through the common sense of the competent operator.

Mathematically, the information must be judged and prepared for use in decision making. If an operator took the time to plot the process information on an X-Y coordinate system, the operator could visually apply a curve fit to the data and come up with a fairly accurate generic representation.

Mathematically, the information must be judged and prepared for use in decision making. If an operator took the time to plot the process information on an X-Y coordinate system, the operator could visually apply a curve fit to the data and come up with a fairly accurate generic representation.

Mathematically, fitting a curve of lower order would produce a fairly inaccurate representation. Therefore, a higher order curve fit would be appropriate to accommodate the noisy signal. Fuzzy Logic attempts to emulate what the human response would be and apply the most intelligent fit to the data.

Ziegler-Nichols control theory

Ziegler-Nichols control theory provides for PID (proportional, integral, and derivative) numbers which aid in the operation of controls. The development of the inexpensive microprocessor based PID control has replaced a majority of the thermostat (on/off) type devices. Most controllers that are microprocessor based have an autotune function which operates a system experiment as shown in figure 2. This experiment helps to determine the thermal characteristics of a particular system. In most cases, the method of autotune is to make a step input into the final control element and monitor the output. This produces a gain term directly related to proportional band. A delay time between the application of the step input and an observed response influences the derivative number.

Most controllers that are microprocessor based have an autotune function which operates a system experiment as shown in figure 2. This experiment helps to determine the thermal characteristics of a particular system. In most cases, the method of autotune is to make a step input into the final control element and monitor the output. This produces a gain term directly related to proportional band. A delay time between the application of the step input and an observed response influences the derivative number.

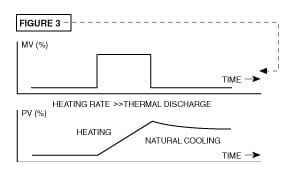

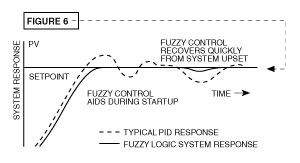

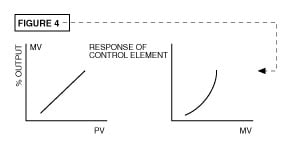

The rise time of the response to the step input produces a value to be used in integration.In some systems, the delay time to produce response is much different than the time to give up heat as shown in figure 3. This is common with many extruder applications making a Fuzzy Logic approach quite beneficial. If the response of the final control element as shown in figure 4 is nonlinear, for whatever reason, a linear response from proportioning action only would result in less than acceptable control.

In addition, if the system tends to have changing thermal properties or some thermal irregularities, Fuzzy Logic control should offer a better alternative to the constant adjustment of PID parameters.

In addition, if the system tends to have changing thermal properties or some thermal irregularities, Fuzzy Logic control should offer a better alternative to the constant adjustment of PID parameters.

Most Fuzzy Logic software begins building its information base during the autotune function. In fact, the majority of the information used in the early stages of system startup come from the autotune solutions.

Applications

Currently there are many applications of Fuzzy Logic utilized by common household devices, products which most people are familiar with. The benefit of Fuzzy Logic becomes transparent to the user of consumer devices since the Fuzzy Module or function is embedded within the product.

The advantage of this approach takes the need for the operator to understand the theory of fuzzy operation away. Operation only requires the application of common knowledge to the standard parameters.

Unless open-loop control is acceptable, almost every process control application would benefit from PID control. In terms of temperature control, good examples are:

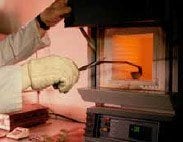

- Heat treatment of metals. “Ramp & Soak” sequences need precise control to ensure desired metallurgical properties are achieved.

- Drying/evaporating solvents from painted surfaces. Over-temperature conditions can damage substrates while low temperatures can result in product damage and poor appearance.

- Curing rubber. Precise temperature control ensures complete cure is achieved without adversely affecting material properties.

- Baking. Commercial ovens must follow tightly prescribed heating and cooling sequences to ensure the necessary reactions take place.

- Ceramics. Continuous kilns must deliver high levels of heat yet are subject to varying thermal loads. This makes them an ideal application for PID control.

Heat treatment of metals

Heat treatment of metals

Commercial baking facility

Commercial baking facility

Key Takaways

Closed-loop control attempts to keep the actual output from a process as close to the target or setpoint output as possible.

PID control is an established method of providing such control, but requires tuning for optimal performance. Such tuning is complex and difficult so heuristic techniques, such as the Ziegler Nichols method, are usually employed.

Processes requiring step change or “Ramp & Soak” control are especially difficult to handle through conventional PID techniques. To address this, controller manufacturers like OMEGA are incorporating fuzzy logic-based auto tuning capabilities. Advanced computational techniques are used to help optimize PID loops, and provide improved levels of process control.